Per ANSI MH271 - Underhung Cranes and Monorail Systems Lbo 2Lo 4. The horizontal component is in part from acceleration and braking while moving load along the monorail.

The monorail beam shall be designed for stresses not exceeding 60 percent of materials yield strength and a maximum vertical deflection.

. Traction power is supplied by power rail installed at both side of concrete beam. There are very few works have been done by the previous researchers for the design of whole monorail system. MONORAIL is a spreadsheet program written in MS-Excel for the purpose of analysis of either S-shape or W-shape underhung monorail beams analyzed as simple-spans with or without overhangs cantilevers.

Top running cranes CMAA classes A to F. Per Dupont Standard DB1X - Design and Installation of Monorail Beams Lbo 3Lo 3. Just like a column in compression the compression flange of a beam can buckle.

Specifically the x-axis and y-axis bending moments as well as any torsion effects are calculated. American National Standards Institute ANSI. RLmin-073 RRmax913 Monorail Size.

Final monorail design. The fleet consists of Von Roll Mk III Monorail type vehicles supported on a straddle-beam guideway using a six-car permanently coupled configuration. MH271 - Underhung Cranes and Monorail Syatems d.

Most liquid and bulk storage structures are constructed in a cir-cular shape which is efficient in resisting pressure from the stored contents. A continuous beam that rides over welded box T-shaped steel supports known as hammerhead. INTRODUCTION The design specifications for monorail crane runway beam are Overhead monorail cranes are used for lifting and transporting according to CMAA 74.

However the design of the supports is not within the scope of this course. Guide wheels are installed at the lower portion of the car to hold the beam at both side and they will support and guide the vehicle. Copyright 2004 Structural Design Concepts Inc All rights reserved.

The Crane Beam Design software will help you design the following. Specifications for top running and objects to the destination point or station for intended under running single girder electric overhead crane under application eg. Connections Bolted andor welded connections can be used on a monorail.

To design and maintain for five years a monorail people mover system which would service the. Our client was concerned about the horizontal sway movement of the supporting steelwork of an existing monorail beam. Reduction of sway movement.

S075 Beam Fy 36 ksi. Code of practice for design - Rolled and welded sections. The type of connection may be driven by the owner ís specification costs and constructability.

H57 Structural 21 Jul 09 0906. This sideways movement of the top flange was what the workers using the monorail had observed. Founded in 1958 in Pickering Ontario Allied Conveyors Limited established a reputation as an industry leader in the design manufacture and installation of premium quality materials handling systems.

74 2004 Job Name. The effect due to continuous beam has been considered while calculating the deflection for cantilever beam under continuous beam condition. Example horizontally curved monorail beams are required where the monorail track must follow a curved path.

449 pages 42-44 1959 Lbo 2Lo for top flange of monorail beam restrained at support Lbo 3Lo for top flange of monorail beam unrestrained at support 5. It has been customary for the structural designers of monorail beams to assume that the wheel loads of four wheel trolleys are equal. Monorail beams are analyzed as single-span beams with or without a cantilever overhang.

The procedure presented for the design of a monorail beam is primarily based on the Crane Manufacturers Association of America CMAA Specification No. Figure 511 indicates the outline of the monorail and Figure 512 indicates the image of the monorail. The software was developed to design with AISC ASD 1989 method with the implementations of AISE report 13.

The burgundy color is intended to. If your plan is to move load along the rail I would not overlook the horizontal components. Monorail track shall be straight and level and specially designed for this application.

Schematic diagram of monorail system I. Design of the monorail beam along with the supports and connections can be an iterative process. Dynamic Engineering performed monorail design checks on these beams.

Per British Steel Code BS. The web tension flange of the beam force the compression flange to buckle sideways which results in the whole section twisting hence torsional buckling. However with more recent trends in hoist design two of the four wheels can carry more than 80 of the total with one wheel carrying more than 40.

Online Steel Beam Calculations W S Beams Standard Channels. Propulsion power is provided by four ABB AC drives running on 600 VAC supplied via side-mounted inverted current collector shoes. American Institute of Steel Construction AISC 9th Edition Allowable Stress Design ASD Manual 1989 e.

MONORAIL BEAM ANALYSIS For S-shaped Underhung Monorails Analyzed as Simple-Spans with without Overhang Per AISC 9th Edition ASD Manual and CMAA Specification No. Ad Quick and Affordable Way to Get Your Steel Beam Calculator in Just Minutes. BS 5950-12000 - Structural use of steelwork in building - Part 1.

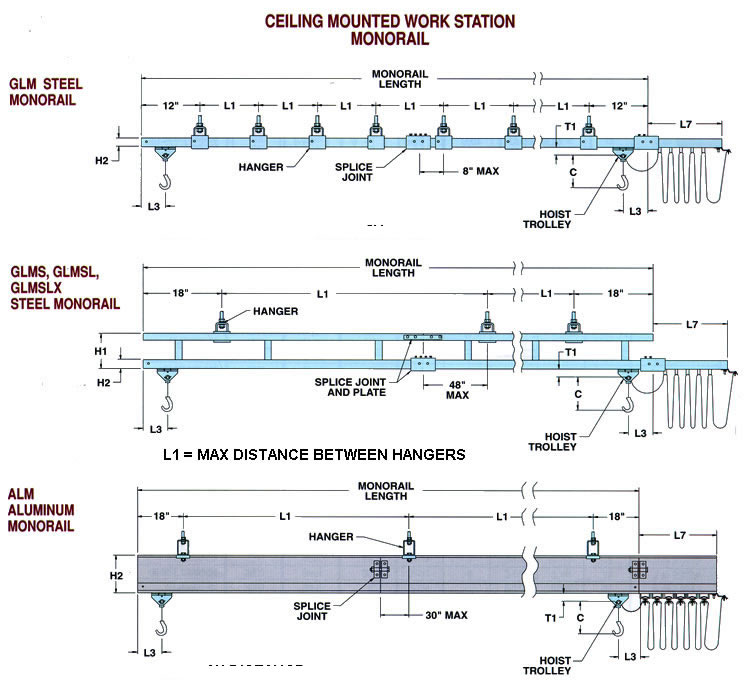

There is one worksheet for S-shaped monorial beams and another worksheet for W-shaped monorail beams. Design calculation of a monorail beam is only a portion of a well-planned overhead material handling system. DB1X - Design and Installation of Monorail Beams May 2000 c.

This sway movement occurred mainly when a team member moved a load along the monorail beam. MONORAILxls is a MS-Excel spreadsheet program for analysis of beam end connections using a tab plate per AISC 9th Edition ASD. Recently acquired by interests in the United States the company now operates under the name Allied Conveyor Systems Inc.

S12x50 x8313 Design Parameters. Dupont Engineering Design Standard. 74 Specifications for Top Running Under Running Single Girder Electric Traveling.

Each train is supported by seven bogies on pneumatic tires. Jike Structural 21 Jul 09 0934. Of the concrete beam.

The general monorail structure design includes the design of runway beam support positions design of supporting structure and connections. National Standards Available British Standard Europe Standard References.

Monorails And Flexural Torsional Buckling If It S Moving It S Broken A Structural Engineer S Take On The World

Craneveyor Corp Jibs Monorails And Gantry Cranes

Monorails Enclosed Track Design Overhead Conveyors

Lateral Buckling Of Monorail Beams Sciencedirect

Straight Lifting Monorail Adei Sas

Monorail Bridge Structure Typical Modules Download Scientific Diagram

0 comments

Post a Comment